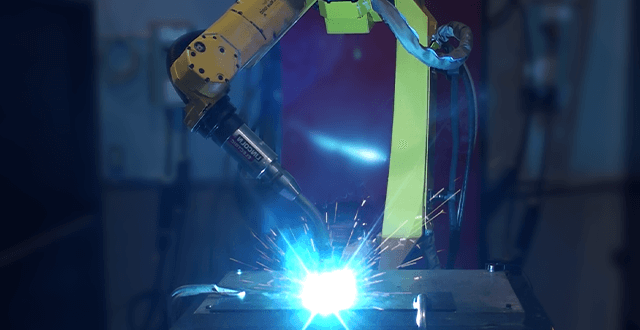

Keep your industrial robots online & working for you

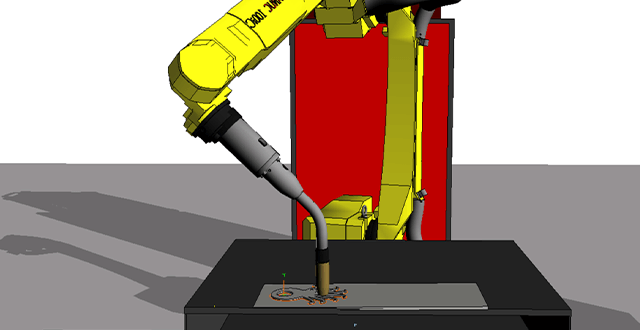

Offline Robot Programming (OLRP) is changing the way integrators and manufacturers program, deploy, and reprogram their robots. By programming robot functions in a virtual, offline environment (on a computer), OLRP eliminates the need for robots to be taken off production, greatly improving productivity and the bottom line.